Contact lens dropout due to dryness is the greatest threat to the contact lens industry. While new wearers are constantly being added to the modality, an estimated 16% per year—that’s one in six wearers!—choose to stop lens wear due to discomfort, creating a stagnant market.1 Keeping our patients comfortable, healthy and happy is our goal as doctors. To this end, we must better understand the concept of lubricity, or the smoothness/slipperiness of one surface relative to another.

Contact lens dropout due to dryness is the greatest threat to the contact lens industry. While new wearers are constantly being added to the modality, an estimated 16% per year—that’s one in six wearers!—choose to stop lens wear due to discomfort, creating a stagnant market.1 Keeping our patients comfortable, healthy and happy is our goal as doctors. To this end, we must better understand the concept of lubricity, or the smoothness/slipperiness of one surface relative to another.

A contact lens’s lubricity determines how it moves on the eye and how the lids blink over the surface. We blink up to 14,000 times each day.2 A dry ocular surface experiences increased friction with the eyelid, elevating the potential to damage either the lid or the ocular surface. Korb found that 74% of contact lens wearers with symptomatic ocular irritation showed signs of lid disruption (lid wiper epitheliopathy) compared to 16% of asymptomatic CL wearers.3 Traumatized lid wiper epithelium may have exposed nerve endings and increased sensitivity, thereby lowering the threshold for dry eye symptoms.4

Studies have also demonstrated that symptoms of dryness are related to the surface wettability/lubriciousness of a contact lens.5 It has been stated that the coefficient of friction is the principal factor associated with end-of-day discomfort.6 Therefore, increasing wettability of the lens surface has been a long-standing strategy for enhancing patient comfort throughout the entire wear period and, as a consequence, keeping patients in contact lenses.

|

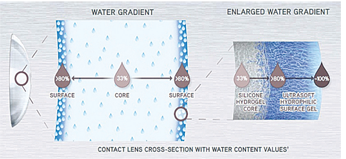

| Schematic of the delefilcon A water gradient design. |

It has always been a challenge to balance the physical properties of contact lenses, including water content, oxygen transmissibility, modulus and surface lubricity. Silicone is best for oxygen transmission, but hydrophobic by nature and requires surface coatings or surfactants to create a wettable surface.

Surface-active agents (surfactants) have bipolar molecules, containing both hydrophilic and hydrophobic ends. When surfactants are used, the hydrophobic ends bind to the dry surface, while the hydrophilic end interacts with the tear film and lid. How strongly the surfactant binds depends on the size of the molecule and the attraction to the lens material; therefore, there are limits to how long a surfactant is active on a lens surface.

The combination of high oxygen permeability provided by silicone-containing lenses and a biomimetic material used to increase hydrophilic properties and decrease protein/lipid build-up is the ultimate goal of lens manufacturers, and potentially the most comfortable lens for our patients.

Clinicians look forward to seeing how this concept performs in practice with the forthcoming launch of the Dailies Total1 lens (Alcon), made of delefilcon A material. This water gradient lens has 33% water content silicone hydrogel core that gradually transitions to over 80% water content in the surface gel, approaching nearly 100% at the very outer surface (which is a 6µm-thick hydrophilic polymer network). The polymer network is anchored to the silicone core and binds water to the lens surface similarly to the way microvilli hold water to the ocular surface, improving biocompatibility with the ocular surface and tear film.

Studies by the manufacturer show that the lens is highly lubricious and maintains its lubricity throughout the day. With sustainable, all-day comfort as our goal, we welcome a new tool that might help thwart contact lens dropout by improving the contact lens-wearing experience.

1. Rumpakis K. New data on contact lens dropouts: An international perspective. Rev Optom. 2010:147(1):37-42.

2. Carney, LG; Hill, RM. The Nature of Normal Blinking Patterns. Acta Ophthalmologica. 1982;(60):427-433.

3. Korb DR, Herman JP, Greiner JV, et al. Lid wiper epitheliopathy and dry eye symptoms. Eye Contact Lens. 2005;31:2-8.

4. McMonnies C. Incomplete blink: exposure keratopathy, lid wiper epitheliopathy, dry eye, refractive surgery, and dry contact lenses. Cont Lens Anterior Eye. 2007;30:37-51.

5. Tonge S, Jones L, Goodal S. The ex-vivo wettability of soft contact lenses. Curr Eye Res. 2001;23:51-9.

6. Coles CML, Brennan NA. Coefficient of friction and soft contact lens comfort. American Academy of Optometry. 2012; E-abstract 125603.