Influenced by clinical feedback that discomfort is the number one cause of dropout, the latest contact lenses have evolved significantly to improve ocular comfort. This is especially true with silicone hydrogel (SiHy) contact lenses, which are supplanting soft hydrogel lenses in popularity. Whereas first-generation SiHy contact lenses emphasized higher oxygenation for extended wear, newer materials have improved comfort without sacrificing the high oxygen permeability of silicone.1

Researchers have been trying to improve comfort by increasing water content, decreasing the modulus, lowering contact angle hysteresis and adding surface coatings and plasma treatments. One study found that over a 10-year period, the water content of SiHy contact lenses has increased from 24% to 74%, and the modulus has decreased significantly from 1.4MPa to 0.3MPa.2 Increased contact lens water content and surface coatings have also led to a notable decrease in contact lens hysteresis, from greater than 40° in lotrafilcon A to less than 10° in delefilcon A.2

Researchers are unsure if lubricity is the only variable that correlates well with in vivo contact lens comfort. So while new, more comfortable materials emerge (though older materials are not eliminated), patients are benefiting from newer, more comfortable silicone hydrogel contact lens materials.3 With wider parameters and replacement modalities, more patients than ever are finding successful contact lens designs that fit their daily needs. This article discusses the latest SiHy contact lens materials and how they affect patient comfort.

|

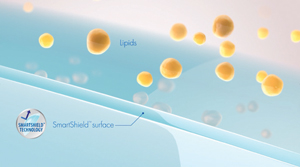

| Air Optix with HydraGlyde’s SmartShield surface surrounds the contact lens and resists lipid deposition. Image: Alcon |

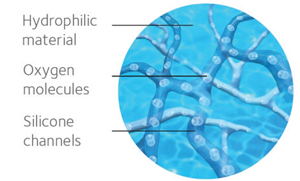

Lotrafilcon B

As an upgrade to Air Optix Aqua (lotrafilcon B), Alcon launched its monthly disposable Air Optix with HydraGylde (lotrafilcon B) to the United States market in 2016. The lens has a 25μm permanent plasma surface treatment, which the company calls ‘SmartShield.’ The continuous hydrophilic layer is designed to help the lens resist lipid deposition. It also uses what the company calls a ‘HydraGlyde moisture matrix,’ which is a block copolymer (poly[oxyethylene]-poly[oxygutylene]) designed to envelop the contact lens in a thin film and create a uniform hydrophilic surface. Both of these technologies are designed to work together to increase the lubricity of the lens and improve contact lens comfort. One study, funded by the manufacturer, found that lotrafilcon B has a significantly lower absorption of cholesterol compared with other SiHy lens materials.4

Delefilcon A

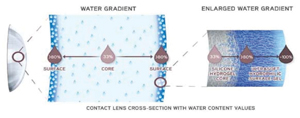

In 2013, Alcon launched Dailies Total1 (delefilcon A), a one-day SiHy contact lens with what’s described by the manufacturer as ‘water gradient technology.’ The lens has a silicone core with 33% water content. The silicone is enveloped in a 6µm thick water gradient created by covalently linked hydrophilic monomers that form a soft, hydrophilic surface gel. According to the company, the lens can achieve greater than 80% water content on the surface.5 The comfort is attributed to the combination of the water gradient technology, low surface modulus of 0.025MPa (core of 0.76MPa), daily disposable modality and packaging in a phosphate-buffered saline solution containing 0.3% polymeric wetting agents (copolymers of polyamidoamine and poly[acrylamide-acrylic acid]).

One study compared the tear break-up time (TBUT), corneal and conjunctival staining and dry eye symptoms in patients randomly assigned to wear one of two different brands of contact lenses. They found that symptomatic dry eye patients who switched to Dailies Total1 had improved comfort by three hours of wear compared with those who switched to Alcon’s Focus Dailies (nelfilcon A), who did not experience any significant comfort improvement.6

Another study compared the wettability and noninvasive TBUT for asymptomatic and symptomatic contact lens patients wearing three different types of daily disposable SiHy contact lenses. The researchers found that Dailies Total1 had reduced dehydration staining and that the ocular and clinical performance of the lenses was not significantly different between symptomatic and asymptomatic contact lens wearers.7 In a cross-over clinical comparison with two other daily disposable SiHy lenses, Dailies Total1 had a longer TBUT, although comfort was similar between the three contact lenses.7,8

|

| This Dailies Total1 cross section illustrates the water gradient throughout the contact lens with water content values. Image: Alcon |

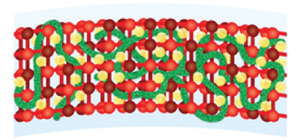

Samfilcon A

In 2014, Bausch + Lomb launched Ultra (samfilcon A), a lens designed with a high level of polyvinylpyrrolidone (PVP) on the lens surface, branded by the company as ‘MoistureSeal Technology.’ Electron microscopy shows silicone wrapped in PVP, and photoelectron spectroscopy reveals PVP on the surface of the lens, creating a hydrophilic surface. PVP is also distributed throughout the lens, allowing for water to be stored within the lens material. This results in a relatively high water content of 46% for a SiHy contact lens.9

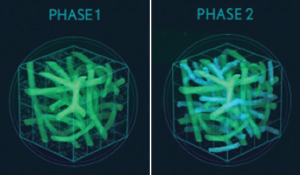

According to the manufacturer, samfilcon A is a combination of three distinct types of silicone that contribute to the balance of high oxygen transmissibility and low modulus. The lens material undergoes two distinct polymerization phases. The first phase involves creating a matrix of long- and short-chained silicone molecules. This is followed by the polymerization of PVP throughout the silicone lattice framework in the second phase.

While no independent studies comparing comfort of Ultra with other contact lenses currently exist, an internal Bausch + Lomb study found that after four hours of lens wear, samfilcon A only dehydrated by 5.07%.10 Another company study used atomic force microscopy and x-ray photoelectronic spectroscopy to evaluate four different contact lenses, each when new and after rub/rinse cycles simulating a month of wear.11 They found little change in the morphology, roughness and composition of samficon A lenses compared with other SiHy lenses.11

| Comparison of Silicone Hydrogel Contact Lenses and Their Comfort Technologies18 | ||||||||

| Contact lens | Manufacturer | Material | Modality | Comfort Technology | Comfort Technology Defined | Water Content | Dk/t | Modulus (MPa) |

| Air Optix Aqua with Hydraglyde | Alcon | Lotrafilcon B | One month | Smart Shield Technology, Hydraglyde Moisture Matrix | Permanent, thin, continuous, hydrophilic plasma coating | 33% | 138 | 1.0 |

| Dailies Total1 | Alcon | Delefilcon A | Single use | Water Gradient Technology | 33% water core, with a water gradient to a hydrogel surface layer that exceeds 80% water at the surface | 33% at core, 80%+ at the surface | 156 | 0.76 |

| Ultra | Bausch + Lomb | Samfilcon A | One month | Moisture Seal Technology | Multiple layers of long-chain silicone integrated with PVP | 46% | 163 | 0.7 |

| Biofinity Energys | Cooper Vision | Comfilcon A | One month | Aquaform Technology | Hydrophilic monomers integrated with silicone; requires no internal wetting agents | 48% | 160 | 0.8 |

| MyDay | Cooper Vision | Stenfilcon A | Single use | Smart Silicone | Minimal efficient use of silicone to allow for a higher water content | 54% | 100 | 0.4 |

| Acuvue Oasys 1-Day | Johnson & Johnson Vision | Senofilcon A | Single use | HydraLuxe Technology | Long-chain, high-molecular weight, PVP internal wetting agent | 38% | 147 | 0.72 |

| Acuvue Vita | Johnson & Johnson Vision | Senofilcon C | One month | HydraMax Technology | Long-chain, high-molecular weight, PVP internal wetting agent | 41% | 147 | 0.77 |

|

| Phase one builds the silicone matrix (green), while Phase two polymerizes PVP (blue) during the production of samfilicon A. Image: Bausch + Lomb |

Comfilcon A

Cooper Vision launched Biofinity Energys in 2016 to address the visual discomfort patients may experience while using digital devices. Energys uses the same material as the company’s Biofinity lens, comfilcon A, but has different optics—called Digital Zone Optics by CooperVision. The optics design is comprised of multiple front-surface aspheric curves across the entire optical zone. The low positive add power in the center of the lens is designed to decrease visual fatigue without sacrificing distance vision while using digital devices. This is to accommodate the increasing digital world, in which 69% of American adults use smartphones on a daily basis compared with only 26% in 2012.12

The Biofinity material uses two types of silicone-based macromers that differ based on molecular weight. These macromers are combined with hydrophilic monomers, resulting in a wettable lens that does not require additional internal wetting agents or surface treatments, according to the manufacturer.

|

| The Energys lens’s Digital Zone Optics are illustrated as a low positive power in the center of the lens. Image: Cooper Vision |

In a clinical study, the original Biofinity lens worn on an extended basis for 30 days over course of a year was compared with another extended wear lens. The researchers found the Biofinity lens was more comfortable, with better vision quality and less limbal redness, bulbar conjunctival hyperemia and conjunctival sodium fluorescein staining.13 Another study showed that Biofinity lenses maintained a relatively low coefficient of friction, indicating greater comfort, even after 100 cycles of simulated wear.14 Its original coefficient of friction value of 0.033 was lower than that of comparable lenses, but not as low as some others that reached values as low as 0.016.14

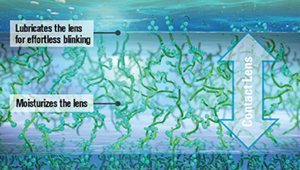

Stenfilcon A

Introduced in 2015, MyDay (stenfilcon A) is Cooper Vision’s most recent one-day disposable contact lens. MyDay is made of covalently linked hydrophilic groups attached to long silicone chains, which the manufacturer calls ‘Smart Silicone.’ Stenfilcon A has a low quantity of silicone—just 4.4%—and this efficient use of the component allows for more space in the contact lens for hydrophilic materials while attaining a 100 Dk/t, a water content of 54% and a low modulus of 0.4MPa, Cooper Vision says.15

Few independent studies on the MyDay lens exists; however, one study found improved hydration performance in hydration profile relative to another SiHy lens, yet both had similar comfort after a 12-hour day.16

|

| Cross section of MyDay’s Smart Silicone illustrates the silicone channels filled with oxygen and large spaces between the silicone channels filled with hydrophilic materials. Image: Cooper Vision |

Senofilcon A

In 2016 Johnson & Johnson Vision launched Acuvue Oasys 1-Day (senofilcon A), a one-day disposable contact lens designed with 38% water and 62% senofilcon A. Though both the two-week disposable Oasys and Oasys 1-Day are made of senofilcon A, J&J says the one-day lens uses an enhanced moisture network that increases the crosslinking density of the silicone with a long chain, high molecular weight, internal wetting agent based on PVP—a process the manufacturer calls ‘HydraLuxe Technology.’17 The chain length and molecular weight PVP is added to a reactive monomer mix and is evenly distributed throughout the lens. The resulting contact lens matrix closely mimics the properties of mucin to improve the comfort as the lens interacts with the patient’s tear film, according to the company. The lens is also packaged in an electrolyte-balanced packaging solution designed to mimic human tears.

Due to the recent launch of these contact lenses, no independent clinical research has been published comparing the comfort of Acuvue Oasys 1-Day with other lenses beyond the internal Johnson & Johnson Vision studies.

|

| Acuvue Oasys 1-Day with HydraLuxe Technology is comprised of a network of hydrated silicone and tear-like molecules that interact with the tear film. Image: Johnson & Johnson Vision |

|

| HydraMax Technology is a network of hydrated, lipophilic silicones (dark red and red) with embedded long chains of pure PVP homopolymer (green). Natural tear lipids (yellow) are integrated into the lens for improved lubricity. Image: Johnson & Johnson Vision |

Senofilcon C

Johnson & Johnson Vision also launched Acuvue Vita (senofilcon C) in 2016. It is a monthly disposable contact lens that uses a non-coated silicone formulation of senofilcon C marketed as ‘HydraMax Technology.’ Senofilcon C is a combination of two types of silicone and has 30% more PVP compared with senofilcon A. The integrated PVP throughout the lens matrix helps with hydration and comfort, without the use of surface treatments. Natural lipid deposits from the tear film are distributed throughout the lens to increase its lubricity and decrease evaporation of the tear film. It also has what the company describes as ‘an infinity edge,’ which is a thin tapered edge designed to improve contact lens comfort.

Because these contact lenses are new, no independent clinical research has been published comparing the comfort of Acuvue Vita with other lenses.

The increasing water content and evolving surface and mechanical properties in these latest SiHy contact lenses show promise for more comfortable contact lens wear. Each company uses a different technology to increase contact lens lubricity—and, interestingly, some of it seems contradictory. For example, the Air Optix with HydraGlyde lens is designed to protect itself from tear lipids, while the Acuvue Vita integrates tear lipids into the lens. The Energys lens does not use internal wetting agents, but Ultra and Acuvue Oasys 1-Day have internal wetting agents based on PVP.

Without vigorous masked, randomized and controlled studies, it is difficult to determine the best contact lens and design feature. To find the right contact lens for each patient, clinicians should have the patient try different contact lens brands. When possible and given that both brands fit well without compromising ocular health, having patients try one brand of contact lenses in one eye and another brand in the other eye allows the patient to experience the comfort of lenses in the same environment. After all, given our current contact lens selection, our patients have many excellent choices to choose from.

Dr. Yeung is a diplomate of the Cornea and Contact Lens section of the American Academy of Optometry and senior optometrist at the University of California, Los Angeles (UCLA), Arthur Ashe Student Health and Wellness Center.

Ms. Sarwar is an undergraduate in the biology department at UCLA. She will graduate in June 2017.

Ms. Hu is an undergraduate in the physiological sciences department at UCLA. She will graduate in June 2018.

1. Sweeney DF, ed. Silicone hydrogels; the rebirth of extended wear contact lenses. Oxford, UK: Butterworth-Heinemann; 2000:214-34.

2. Tighe BJ. A decade of silicone hydrogel development: surface properties, mechanical properties, and ocular compatibility. Eye & Contact Lens. 2013:39;4-12.

3. Jones L, Brennan NA, Gonzalez-Meijome J, et al. The TFOS international workshop on contact lens discomfort: report of the contact lens materials, design, and care subcommittee. Invest Ophthalmol Vis Sci. 2013;54:TFOS37-70.

4. Nash WL, Gabriel MM. Ex vivo analysis of cholesterol deposition for commercially available silicone hydrogel contact lenses using a fluorometric enzymatic assay. Eye & Contact Lens. 2014;40(5):277-82.

5. Stone R. Introducing water gradient technology. CL Spectrum. 2013;28(13):34-8.

6. Michaud L, Porcier P. Comparing two different daily disposable lenses for improving discomfort related to contact lens wear. Cont Lens Anterior Eye. 2016;39:203-9.

7. Varikooty J, Schulze MM, Dumbleton K, et al. Clinical performance of three silicone hydrogel daily disposable lenses. Optom Vis Sci. 2015;93(3):301-11.

8. Wolffsohn JS, Mroczkowska S, Hunt OA, et al. Crossover evaluation of silicone hydrogel daily disposable contact lenses. Optom Vis Sci. 2015;92(11):1063-8.

9. Wygladacz K, Hook D, Steffen R, et al. Breaking the cycle of discomfort. CL Spectrum. 2014;29(13):23-8.

10. Steffen R, Hook D, Schafer J, et al. New technology yields dehydration resistance. Paper presented at the American Academy of Optometry, November 14, 2014; Denver.

11. Merchea MM, Wygladaca KA, Hook D. Comparative surface smoothness durability of a novel silicone hydrogel material. IOVS. 2014;55:6063.

12. The Vision Council. Digital Eye Strain Report. 2015. www.thevisioncouncil.org/sites/default/files/VC_DigitalEyeStrain_Report2015.pdf. Accessed April 4, 2017.

13. Brennan N, Coles C, Connor H, et al. A 12-month prospective clinical trial of comfilcon A silicone-hydrogel contact lenses worn on a 30-day continuous wear basis. Contact Lens & Anterior Eye. 2007;30:108-18.

14. Roba M, Duncan EG, Hill GA, et al. Friction measurements on contact lenses in their operating environment. Tribol Lett. 2011;4(3):87-97.

15. Kading D. New lens technology targets improved vision and comfort. Contact Lens Spectrum. 2014;29:19.

16. Panjwani F, Papinski D, Varikooty J, et al. In-vivo dehydration of stenfilcon A and delefilcon A silicone hydrogel materials. Poster presented at the AOA, October 9, 2015; New Orleans.

17. Keir N, Jones L. Wettability and silicone hydrogel lenses: a review. Eye Contact Lens. 2013;39(1):100-8.

18. Thompson TT. Tyler’s quarterly soft contact lens parameter guide. TQ Mar. 2017;34(2):1-65.