Soft contact lenses are big business: in 2010, the soft lens market in the United States was estimated at $2.1 billion, with an approximate growth of 5% per year since, despite a contact lens dropout rate of 15% to 25%, depending on which study is considered.1-3,18 One of the primary reasons for discontinuing wear is contact lens discomfort (CLD), with estimates of greater than 50% of patients having symptoms of discomfort or dryness while wearing contact lenses.3 With much at stake and a clear culprit in the form of discomfort, naturally much of the innovation coming out of contact lens R&D labs focuses on ameliorating CLD.

In 2013, the Tear Film and Ocular Surface Society (TFOS) published results of a workshop that sought to define, classify and determine the factors contributing to CLD. These experts defined CLD as any adverse sensation resulting from reduced compatibility between the contact lens and the ocular environment.4 When managing CLD in the absence of significant ocular surface disease, many practitioners will often change contact lens materials or modality as a first line of treatment.

This article will review how different contact lens properties can impact comfort, and how recent innovations are reshaping the daily disposable soft lens market.

| |

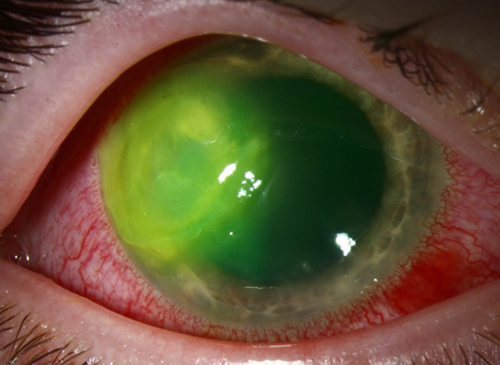

| Unsafe contact lens wear can cause corneal ulcers, like this Pseudomonas case. Photo: Christine W. Sindt, OD |

The DK Dilemma

The physical properties of a specific soft contact lens are largely manipulated by the monomers that make up each polymer in the lens. Dating back to the first soft contact lens, most hydrogels contain poly-2-hydroxyethyl methacrylate (HEMA), which has a low oxygen permeability (DK). Increasing the water content results in a logarithmic increase in DK; however, to maintain stability and reduce lens dehydration, the center thickness must be increased, effectively reducing oxygen transmissibility (DK/t).5

Adding silicone to soft hydrogel lens polymers increases the level of oxygen that flows to the cornea. Oxygen is highly transmissible in silicone, with an inverse relationship to water content.5 First generation silicone hydrogel lenses (SiHys) contained high levels of silicone with a lower water content, allowing for a highly oxygen permeable, but higher modulus lens.

Although SiHys reduce the risk of hypoxic complications, they are not without their own challenges. Silicone is inherently hydrophobic, which can lead to increased lipid deposition and wettability concerns.5 Higher modulus lenses can also induce complications from mechanical interaction with conjunctival tissue. However, newer generation SiHys are able to increase the water content to decrease modulus, while still maintaining a higher DK/t.6

Contact Lens Properties

A number of lens characteristics exist with varying influences on patient comfort.

• Oxygen Transmission. Clinical experience may suggest some early resistance when moving long-time lower DK/t hydrogel lens wearers to higher DK/t SiHy lenses, as increased corneal sensitivity can lead to initial discomfort. In general, most studies indicate a higher subjective level of comfort in SiHys vs. hydrogels; research shows evidence to the contrary.7,8 Additionally, when comparing different SiHys, no evidence shows that comfort is dependent on DK.9,10

• Water Content and Dehydration. In vitro studies indicate lower water content lenses exhibit less dehydration.11 While it is reasonable then to conclude that CLD with higher water content lenses is due to dehydration, there has been no definitive correlation.12 This in part may be attributable to other factors influencing in vivo dehydration, including the tear film and environment.

• Lens Deposition. In addition to water content, HEMA lenses are classified by ionic charge. Lenses with a negatively charged surface will attract more positively charged tear film proteins, which if denatured can lead to a decreased tear break up time and decreased comfort.13 SiHys tend to bind lipids more than proteins, which may contribute to contact lens-induced inflammation. Surprisingly, there is no evidence of significant correlation between protein or lipid deposition to decreased comfort.14

• Friction or Lubricity. The friction force between a contact lens and palpebral conjunctiva is commonly described in the context of lubricity. As the reciprocal of friction, when lubricity is high, friction is low. Correlating in vitro measurements of friction to comfort can be difficult, and studies are limited; however, current data available suggests a direct relationship. Lower levels of friction is highly predictive of higher comfort levels.15,16

• Surface Wettability. Wettability is used to describe how the tear film spreads out over the surface of the contact lens. This often correlates to lubricity, as a better wetting lens reduces the friction forces on the contact lens surface. Researchers suggest that thinning of the pre-lens tear film is highly indicative of CLD; however, they are less clear on whether that is a result of a previously unstable tear film or an interaction between the lens surface and tear film.12

• Wetting Agents. Wetting agents are commonly used to aid in providing superior end-of-day comfort. These may include polyvinyl alcohol (PVA), polyvinylpyrrolidone (PVP) and hyaluronic acid (HA). The additives can be incorporated into the lens matrix to retain moisture and improve surface wettability. No evidence shows that wetting agents directly improve comfort.17

| Beyond Dailies |

Recent Innovations and Trends

Although daily disposable lenses were initially introduced in the 1990s, the last few years have witnessed the most rapid growth of this modality. In 2014, nearly 30% of all soft contact lenses prescribed were daily disposables.1 A large part of this growth is due to recent innovations in contact lens technology.

• Hydrogels. Several of the newest daily disposable hydrogel lenses on the market incorporate unique properties to achieve comfortable wear.

While most wetting agents are bound within the contact lens to help retain internal moisture, Dailies Aqua Comfort Plus (Alcon) lenses use “blink activated” moisture technology. The nelafilcon A polymer contains several moisturizing agents, including hydroxypropyl methylcellulose (HPMC), polyethylene glycol (PEG) and PVA. Additional HPMC is also added to the saline contained within the packaging to improve initial comfort. When wearing the lenses, the blinking mechanism releases these wetting agents on the lens surface over a 20-hour period, allowing for continuous tear film stability.

A different approach to retaining moisture is to mimic the ocular surface. BioTrue OneDay (Bausch + Lomb) lenses have a 78% water content, which matches the water content of the cornea. The HyperGel material combines a nesofilcon A polymer with a surfactant on the lens surface to mimic the lipid layer of the tear film. Although higher water content lenses typically dehydrate more, this combination forms a dehydration barrier retaining moisture within the lens.

One of the latest hydrogel daily disposables to reach the market is the Miru (Menicon), made with the well-known polymer hioxifilcon A. This pHEMA and glycerol methacrylate copolymer (HEMA-GMA) binds tightly to water, resisting dehydration more than a typical pHEMA high water content lens. Its smooth edge design also reduces eyelid friction while blinking. The contact lens is packaged with the outside surface facing up in a one-millimeter thin flat pack to help prevent contact with the inner surface before insertion on the eye, thus improving lens hygiene.

• Silicone Hydrogels. In 2014, silicone hydrogels accounted for nearly 70% of the soft lens market.1 Although silicone hydrogel lenses make up the majority of the monthly and two-week modalities, they have only recently become an option as daily disposables.

The first silicone hydrogel daily disposable to reach the United States market was the 1-Day Acuvue TruEye (J&J Vision Care). First released using the narafilcon B polymer, it later became available as narafilcon A, which increased the DK/t from 65 to 118. To counter the hydrophobic nature of silicone, PVP is added to the lens as an internal wetting agent.

The Dailies Total1 (Alcon) features an interesting type of water gradient polymer. While technically a silicone hydrogel, the delefilcon A core is 33% water, which transitions to greater than 80% water at the lens surface. This allows for not only the highest oxygen transmission of any daily disposable with a DK/t of 156, but its hydrophilic surface makes it a highly wettable and lubricious lens.

In addition to spherical lenses, the Clariti 1-Day (Cooper Vision) family of lenses offers both toric and multifocal options. Using the somofilcon A polymer, these lenses balance many of the desired attributes for a contact lens. With a 56% water content and a proprietary hydrophilic surface, these lenses have both a lower modulus and coefficient of friction.

| |

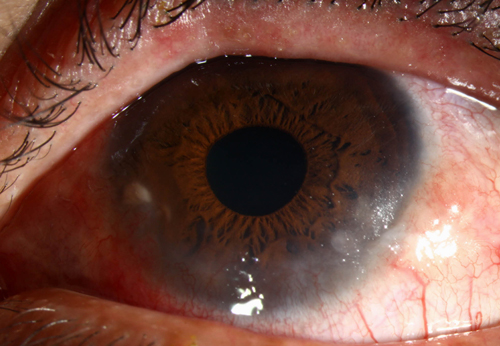

| Better soft contact lenses may also help prevent the development of corneal infiltrates. Photo: Christine W. Sindt, OD |

• Multifocals. While there is little evidence to support the notion that CLD is directly associated with age, many practitioners would acknowledge that CLD and dry eye are a common concern with presbyopic patients.19 With the increasing demands on near vision, there is more need than ever for daily disposable multifocal lenses.

There are four center-near daily multifocal options: Dailies Aqua Comfort Plus Multifocal (Alcon), Clariti 1-Day Multifocal (Cooper Vision), BioTrue OneDay for Presbyopia (Bausch + Lomb) and the Proclear 1-Day Multifocal (Cooper Vision). These lenses use the same technologies as their spherical counterparts. The Proclear 1-Day multifocal, for example, uses the omafilcon A material with a 62% water content. The polymer structure resembles phospholipids, which can attract and bond with water and reduce dehydration.

Interestingly, while most recent strides have been made with comfort in mind, two new daily disposable lenses set to roll out this year showcase multifocal optics not available in the more commonly used monthly modality. The 1-Day Acuvue Moist Multifocal (J+J Vision Care) is a center-distance design with a pupil diameter optimization that changes with add power. The NaturalVue 1-Day Multifocal (Visioneering Technologies) is inspired by a camera aperture and is designed to provide an enhanced depth of focus.

• Enhancers. Long available in Asian markets, the 1-Day Acuvue Define (J&J Vision Care) contact lenses are rolling out in the United States market this year. Designed to enhance natural beauty of the eye, these lenses increase the contrast between iris color and the sclera. Rather than the color pixels being imprinted on the surface, however, the design pigments are encapsulated within the etafilcon A polymer.

When patients present with CLD, careful evaluation of both contact lens fit and the ocular surface is warranted. In mild cases, refitting the patient with a different lens may resolve this discomfort. Most of the recent innovation involves contact lens surface technology, which impacts dehydration, lubricity, wettability and deposition rates. Although it can be difficult to ascertain which lens attribute will improve contact lens comfort for each individual, there is no shortage of daily disposable lenses at our disposal.

Dr. Ensley is in private practice in Louisville, Kentucky, where he specializes in fitting specialty contact lenses. He completed a residency in cornea and contact lenses at the University of Missouri-Saint Louis and is a Fellow of the American Academy of Optometry.

1. Nichols JJ. Contact lenses 2014. Contact LensSpectrum 2015;30(1):22-27.

2. Dumbleton K, Woods CA, Jones LW, Fonn D. The impact of contemporary contact lenses on contact lens discontinuation. Eye Contact Lens. 2010;39(1):93-9.

3. Richdale K, Sinnott LT, Skadahl E, Nichols JJ. Frequency of and factors associated with contact lens dissatisfaction and discontinuation. Cornea. 2007;26(2):168-74.

4. Nichols KK, Redfern RL, Jacob JT, et al. The TFOS International Workshop on Contact Lens Discomfort: Report of the Definition and Classification Subcommittee. Invest Ophthalmol Vis Sci. 2013;54:TFOS14–TFOS19.

5. Henry VA, DeKinder JO. Soft lens material selection. In: Bennett ES, Henry VA, ed. Clinical Manual of Contact Lenses. 4th Ed. Philadelphia, PA: Lippincott, Williams & Wilkins; 2014: 252-69.

6. Tighe BJ. A decade of silicone hydrogel development: surface properties, mechanical properties, and ocular compatibility. Eye & Contact Lens. 2013;39:4-12.

7. Fonn D, Dumbleton K. Dryness and discomfort with silicone hydrogel contact lenses. Eye Contact Lens. 2003;29:S101– S104

8. Cheung SW, Cho P, Chan B, Choy C, Ng V. A comparative study of biweekly disposable contact lenses: silicone hydrogel versus hydrogel. Clin Exp Optom. 2007;90:124– 31.

9.Dumbleton KA, Woods CA, Jones LW, Fonn D. Comfort and adaptation to silicone hydrogel lenses for daily wear. Eye Contact Lens. 2008; 34(4):215-23.

10. Brennan NA, Coles ML, Connor HR, McIlroy RG. A 12-month prospective clinical trial of comfilcon A silicone-hydrogel contact lenses worn on a 30-day continuous wear basis. Cont Lens Anterior Eye. 2007;30:108–18.

11. Jones L, May C, Nazar L, Simpson T. In vitro evaluation of the dehydration characteristics of silicone hydrogel and conventional hydrogel contact lens materials. Cont Lens Anterior Eye. 2002;25:147–56.

12. Nichols JJ, Sinnott LT. Tear film, contact lens, and patient-related factors associated with contact lens-related dry eye. Invest Ophthalmol Vis Sci. 2006;47:1319-28.

13. Subbaraman LN, Glasier MA, Varikooty J et al. Protein deposition and clinical symptoms in daily wear of etafilcon lenses. Optom Vis Sci. 2012;89(10):1450-9

14. Zhao Z, Naduvilath T, Flanagan JL, et al. Contact lens deposits, adverse responses, and clinical ocular surface parameters. Optom Vis Sci. 2010;87:669–74.

15. Coles CML, Brennan NA. Coefficient of friction and soft contact lens comfort. Optom Vis Sci. 2012;88:e-abstract 125603.

16. Kern J, Rappon J, Bauman E, Vaugh B. Assessment of the relationship between contact lens coefficient of friction and subject lens comfort. Invest Ophthal Vis Sci. 2013;54: ARVO E-abstract 494.

17. Jones L, Brennan NA, Gonzalez-Meijome J, et al. The TFOS International Workshop on Contact Lens Discomfort: Report of the Contact Lens Materials, Design, and Care Subcommittee. Invest Ophthalmol Vis Sci. 2013;54:TFOS37–TFOS70.

18. Nichols JJ. Contact Lenses 2010. Contact Lens Spectrum. January 2011.

19. Dumbleton K, Caffery B, Dogru M, et al. The TFOS International Workshop on Contact Lens Discomfort: Report of the Subcommittee on Epidemiology. Invest Ophthalmol Vis Sci. 2013;54:TFOS20–TFOS36.